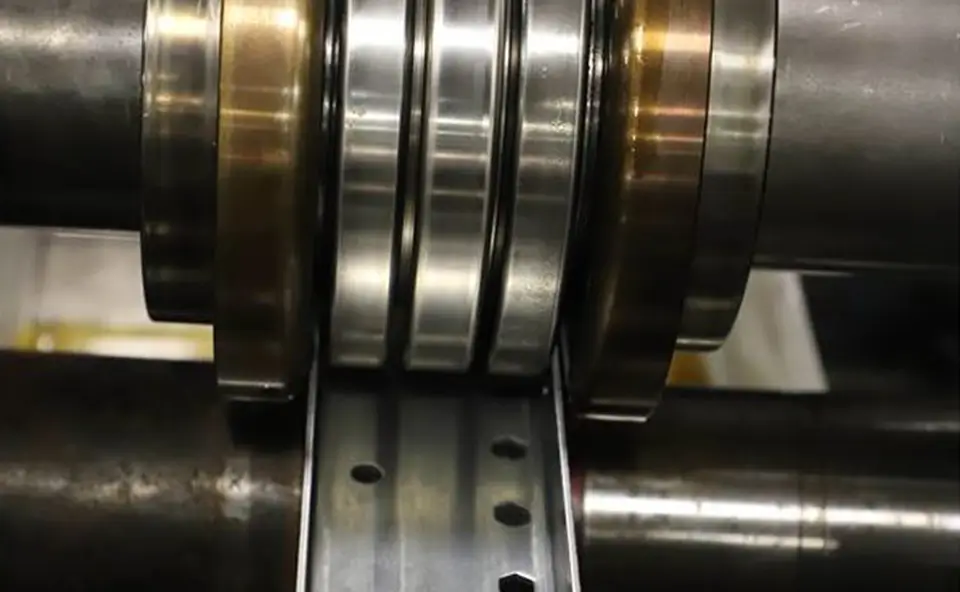

COLD FORMING TOOLING

At Header, our primary goal is to produce tooling that lasts as long as possible.

Since 1954, we have been helping our customers double or even triple the life of their tooling, keep their machines running, produce more parts without the need to change inserts or die assemblies, and increase overall productivity and profitability. In addition, more reliable tooling reduces the need to purchase parts. Several case studies document how the Header team has worked with clients to get our tooling to last an entire run, compared to past runs that required three sets of tooling to achieve the same part count.

Our Customer Base

Header's customer base produces parts that include externally threaded fasteners, munitions, rivets, bearings, medical equipment, medical tablets, battery terminals, electric connectors, and more.

Header has experts that partner with our clients to help select the right materials to maximize their die life. We work closely with outside engineers and other industry experts to ensure the highest quality tooling is produced so that the best possible parts are being made to the individual industry standards.

Expert Capabilities

Header has expert capabilities to produce both carbide and steel inserts. Many shops will only work with one aspect of tooling or another, whether that is just pins, casings, or inserts. Here at Header, we are comfortable manufacturing entire tool packages that include every bit of tooling necessary to produce the completed product. That includes the feed wheels, quills, cut-offs, knives, transfer fingers, dies assemblies, punches, knockouts, and anything else required.

CONTACT HEADER DIE & TOOL

See what we can do for you today!